Response

From supplying all manner of personal protective equipment to actually reaching out to those on the front lines, Georgia Tech's response to the world's most formidable health challenge in living memory has been swift and unswerving.

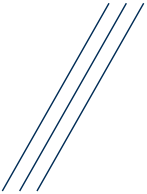

To help meet the need for PPE for healthcare workers, Georgia Tech designed and produced face shields using a laser-cutting machine (above at the Flowers Invention Studio) to create frames for the shields.

1.8 Million Face Shields Delivered to Protect Medical Workers From Covid-19

Personal initiatives by a pediatrician and by researchers to make face shields for medical workers have transformed into an industry collaboration that has delivered 1.8 million shields to hospitals around the country, with plans to produce 2.5 million all told. A $2 million donation from Aflac Incorporated for personal protective equipment (PPE) financed the bulk of the shields.

To make it happen, a team of researchers and industry partners convened at the Global Center for Medical Innovation (GCMI), a Georgia Tech-affiliated nonprofit organization that guides new experimental medical solutions to market.

A Physician’s Wisdom

The situation was urgent, and I knew who would have the right expertise to get this done."

—Sherry Farrugia, Chief Operating Officer and Strategy Officer, Children’s Healthcare of Atlanta Pediatric Technology Center

The project grew wings in mid-March, after Dr. Joanna Newton became concerned about the nationwide shortage of PPE leaving healthcare workers all over the country vulnerable. Newton is a physician specializing in improving healthcare safety through technology at Children’s Healthcare of Atlanta, and she was already collaborating with Georgia Tech on other projects.

She grabbed the phone to leverage the connection.

“I called Sherry Farrugia to tell her about my idea to 3D-print PPE,” said Newton, a pediatric hematologist/oncologist at the Aflac Cancer and Blood Disorders Center of Children’s.

“The situation was urgent, and I knew who would have the right expertise to get this done,” said Farrugia, chief operating officer and strategy officer of Children’s Healthcare of Atlanta Pediatric Technology Center, which is part of Georgia Tech.

Farrugia had Newton present her idea at GCMI to researchers, advisors, and industry partners who immediately fused to a team.

Bringing in Engineers

At the same time at Georgia Tech, Samuel Graham, chair of the George W. Woodruff School of Mechanical Engineering, and Susan Margulies, chair of the Coulter Department of Biomedical Engineering, were coordinating efforts across campus to develop medical devices in response to the Covid-19 pandemic. Graham and Margulies connected GCMI with engineering researchers Christopher Saldana and Saad Bhamla, who were leading an effort to address the face shield problem with their students.

“The Georgia Tech mechanical engineering team used rapid fabrication equipment and quickly produced multiple face shield designs that could be manufactured in high volumes for the rapid response that Covid-19 required,” Saldana said.

Making a few thousand shields in a lab had already saved lives, but the Georgia Tech researchers and GCMI put their designs on the internet, where they have been downloaded some 1,400 times. And the manufacturing partners they engaged have been turning out hundreds of thousands of shields to save many more lives.

“You may need 45 minutes for a headband with a 3D printer, but manufacturers turn out six of them every 19 seconds. Then making a million face shields becomes a real possibility,” said Mike Fisher, who leads product development at GCMI.

GCMI opened a GoFundMe page, which brought in $20,000, and then engaged their first manufacturing partner, Delta Air Lines.

This animated map shows the distribution paths for the 2.5 million face shields.

A Manufacturing Explosion

“Delta converted one of their groups from manufacturing airplane interiors to doing the face shields. They started off by manufacturing 6,000 shields, and that got the momentum going,” said Amy Leiter, senior advisor at GCMI. “Two thousand shields went to Mount Sinai Hospital in New York; 2,000 went to Piedmont Healthcare in Atlanta, and 2,000 went to Children’s Healthcare of Atlanta.”

Things began to snowball, including at Delta, which produced 100,000 shields.

Graham engaged Siemens Industries to fulfill a face shield order from the Georgia Emergency Management Agency for distribution in Georgia. Other manufacturers came on board, and Aflac volunteered to donate funding.

“We asked for a donation of $500,000 for manufacturers to retool their operations. Aflac made a gift of $2 million to GCMI to promote the production of PPE,” Farrugia said. “We were able to buy tooling to refit an automotive plastics manufacturer called Quality Model in South Carolina, for mask production.”

GCMI won a bid from the Federal Emergency Management Agency for 1,141,600 face shields, which Quality Model is producing along with thousands more. About half a dozen partners are producing the rest of the 2.5 million shields. They will go to medical facilities in need all across the country.

The target total of 2.5 million face shields will be delivered to medical facilities all across the nation.

Tech Creates Rapid Response Website Specifically for Covid-19 Needs

As part of the response to the Covid-19 crisis, Georgia Tech established a Rapid Response website to identify needs for personal protective equipment (PPE) and potential collaborations.

Hand sanitizer, disinfectant wipes, face shields, respirator masks, and ventilators have all been identified as critical needs.

"With the significant challenges on our supply chain, we need strategies to provide personal protective equipment for healthcare staff," said Dr. Charles Brown, CEO of Physician Enterprise at Piedmont Healthcare. "We have mechanisms in place to develop ideas and are working with Georgia Tech and the Global Center for Medical Innovation (GCMI) to advance them to what we can use."

Georgia Tech faculty members, students, and GCMI worked on multiple face shield designs, talking with clinicians at Children’s Healthcare of Atlanta, Emory Healthcare, and Piedmont to evaluate and iterate.

While the face shield was the most mature of the projects the team developed, researchers also looked at other needs within the medical community.

Leon Williams, head of the Centre for Competitive Creative Design at Cranfield University, worked with Tech researchers to create a makeshift ventilator based on the bag-valve-mask (BVM) – also known as an Ambu bag – a handheld mechanical resuscitation device already available at hospitals.

As with face shields, the group expects to make its plans widely available for other groups to iterate and produce. “Simple solutions using motors that people can get anywhere, structures that can be 3D-printed, and materials that can be hand-cut with saws may get us through this,” said Shannon Yee, associate professor in Tech’s George W. Woodruff School of Mechanical Engineering, who’s working on the ventilator issue with a half-dozen colleagues at Tech and other universities.

Grey HR Article Div

Truckloads of Personal Protective Equipment Donated for Healthcare Workers

On March 27, 2020, workers from Tech’s Department of Environmental Health and Safety (EHS) shipped at least eight pallets of much-needed personal protective equipment (PPE) to healthcare workers.

EHS worked hand-in-hand with the Georgia Tech Police Department to gather PPE from buildings across campus. The teams included a small crew of only essential campus workers who pulled together 167,900 gloves, more than 3,700 surgical and N95 masks, 6,000 shoe covers, and thousands of other items like eye protection, protective coveralls, and cleaning supplies — all from scientific labs where work had been on pause.

The donated PPE was all procured from scientific labs where work had been paused.

Twitter: CocaCola PPE

Partnering for PPE

"Our neighbors at @CocaColaCo here in Atlanta brought 6,000 pounds of plastic sheeting to campus, where our students and faculty will use it to make more than 50,000 plastic surgical shields to be donated to hospitals across our area as we battle COVID-19." #SwarmStrenGTh

Video: Emory and Georgia Tech create barrier protection devices for use during COVID-19

Emory and Georgia Tech Create Barrier Protection Device for Use During Covid-19

Working with another major Atlanta university, Georgia Tech has created a barrier protection device designed to reduce the risk of disease transmission during those risky moments when healthcare workers are inserting and removing breathing tubes, increasing their exposure to respiratory droplets.

“The goal is to shroud the patient and allow the clinicians to do the necessary procedures while adding an additional barrier from potential exposure,” said Georgia Tech’s Christopher Saldana, an associate professor in the George W. Woodruff School of Mechanical Engineering.

Unlike the face shields and respirators that are in such high demand, the barrier protection device will be needed only in small quantities to shield clinicians during the specific procedure. Hospitals potentially could find it useful in emergency departments, intensive care units, and operating rooms.

Business Student Initiates Encouragement Efforts for Frontline Workers

Business Student Initiates Encouragement Efforts for Frontline Workers

“Letters of Love is based on the idea that people do not have to leave their homes to serve their community,” says Claudia Onley, a third-year business administration major at Tech. “All they have to do is go online and type some words of encouragement.”

Anyone can write a note for Letters of Love. Writers can also specify if they want their letter delivered to healthcare workers, grocery store clerks, mail workers, or other essential employees. Onley, her family, and her friends will then either transfer the message to a physical letter and deliver it, or send it virtually if needed.

Pinar Keskinocak

Tech Features Prominently Nationally for its Coronavirus Expertise

When the coronavirus pandemic began to spread across the United States, journalists turned to a variety of Georgia Tech experts to help them make sense of the crisis.

Pinar Keskinocak and Joshua Weitz have been two of the most prominent voices for those reporters.

Keskinocak, William W. George Chair and Professor in the H. Milton Stewart School of Industrial and Systems Engineering, has long studied how societies manage global disease outbreaks, and how outbreaks tax the healthcare system and wrack supply chains.

She wrote guest pieces for the New York Daily News, The Hill, and the Atlanta Journal-Constitution; and spoke to NPR, the Financial Times, and CNN, among others. Her research group’s models of demand for medical facilities and supplies also provided essential insight to Georgia Gov. Brian Kemp’s Covid-19 Task Force.

Weitz’s Covid-19 Event Risk Planning Tool has been written about in every major city across the country as Americans weigh the risks of various activities. The interactive map allows users to see the potential for encountering someone who is positive for Covid-19 at an event, given the event’s location and size.

Weitz, a Patton Distinguished Professor in the School of Biological Sciences at Georgia Tech and director of the Interdisciplinary Ph.D. in Quantitative Biosciences, is a quantitative biologist who specializes in disease dynamics. Writers from The New York Times, Slate, National Geographic, and other publications have relied on him to understand the spread of the virus. He also has helped Tech plan for the fall semester and implement widespread surveillance testing.

Both modelers continue their studies as the pandemic evolves, helping decision-makers and the public understand what’s happening — and what’s to come.

Joshua Weitz

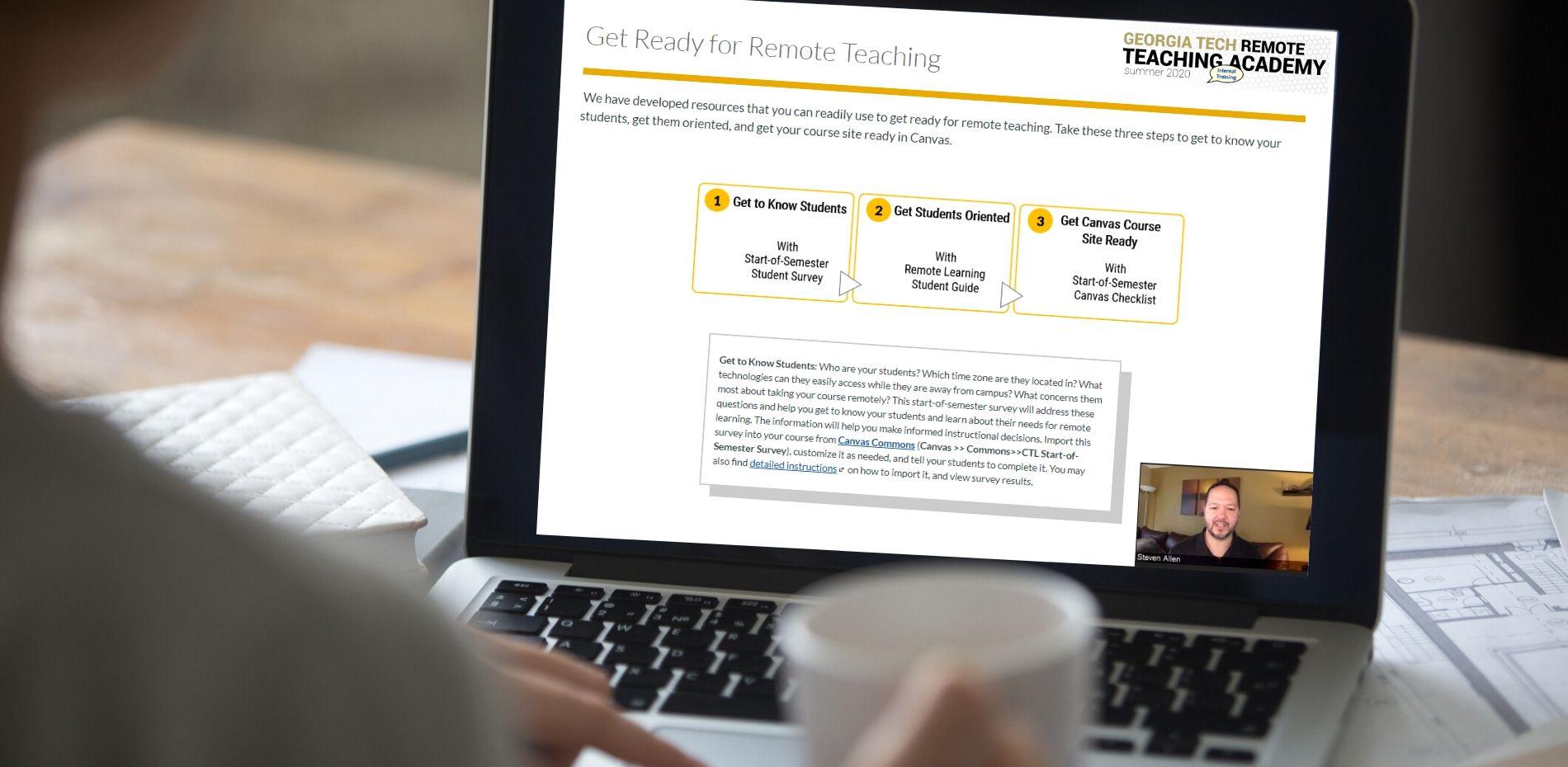

GTPE Employs 50 Years of Experience to Lead Transition to Virtual Learning

The Georgia Tech Remote Teaching Academy

GTPE Employs 50 Years of Experience to Lead Transition to Virtual Learning

When coronavirus made remote learning an overnight reality, Georgia Tech was uniquely positioned to provide support, thanks to Georgia Tech Professional Education (GTPE), the Institute’s lifetime education arm with nearly 50 years of experience in online and distance education. GTPE’s personnel and longstanding expertise in education technology, distance delivery, and virtual engagement enabled the Institute to make the transition to remote instruction seamlessly.

In collaboration with other leaders and units across campus, members of the GTPE executive leadership team quickly developed a training program to support faculty as they navigated the new reality. Nisha Botchwey, associate dean of Academic Programs, and Yakut Gazi, associate dean for Learning Systems, served as co-directors. The curriculum of the Georgia Tech Remote Teaching Academy not only provided a broad training regime, but also ensured quality in teaching activities in a remote setting.

"I can't think of a better example of pulling together resources and partners in a way that advances the human condition through technology," Botchwey said.

And while GTPE was front and center to help quickly pivot the Institute to remote learning, their involvement didn’t stop there. It continued far beyond the Tech campus.

Amid the ongoing public health crisis, GTPE’s experts served as thought leaders, providing insight on the difference between remote delivery and true online education to the larger higher education and business communities through virtual conferences, academic publications, podcasts, and more.

In a May podcast, Dean of Professional Education Nelson Baker discussed how to navigate change and the educational opportunities emerging amidst rebuilding in the Covid-19 era and beyond.

In July, Yakut Gazi, associate dean of Learning Systems, made the case in the Academic Leader that the student-centric approach of online education has the potential to change higher ed for the better after the pandemic, predicting that “both faculty and students will experience a shift in mindset that leads to better educational outcomes.”

And, taking on new relevance during Covid-19, an annual signature event for Georgia Tech, the Affordable Degrees-at-Scale, was moved virtually and brought together leading innovators from around the world for a conversation about the next frontier of learning — at-scale education — and its economic and workforce benefits, and its power to connect people.

Innovation

Innovative thinking and doing has always been at the heart of everything Georgia Tech. Never has that been more evident than in our efforts put forward in the fight against Covid-19.

Kolby Hanley with his 3D-printed respirator part. Photo courtesy of ULTRAVIEW Archery LLC

Yellow Jackets Leverage Just-in-Time Manufacturing to Create Respirator Parts

A recent materials science engineering graduate, Kolby Hanley, has turned his company’s warehouse, using all of his 3D printers, into a rapid response center to create respirator parts.

Hanley partnered with Lee Whitcher, a fellow Yellow Jacket majoring in aerospace engineering, who spearheads the group AtlantaBeatsCOVID.com. Their consortium is comprised of makers from the Atlanta community who feel they have something to contribute to the fight against Covid-19.

“I put out a call to everyone I knew, and, within 24 hours, I had 60 people from makerspaces all over the Atlanta area,” said Whitcher. “Kolby expressed an interest in helping with his vast array of 3D printers that his company UltraView traditionally uses to make archery parts.”

Hanley’s facility specializes in rapid prototyping, which made it a perfect place to 3D-print molds based on Whitcher’s designs. These molds are then used to create the respirator parts that fit over a patient’s nose and mouth to facilitate breathing.

The ultimate goal is for everything to be open sourced with directions on how to use the kits to make the respirator masks.

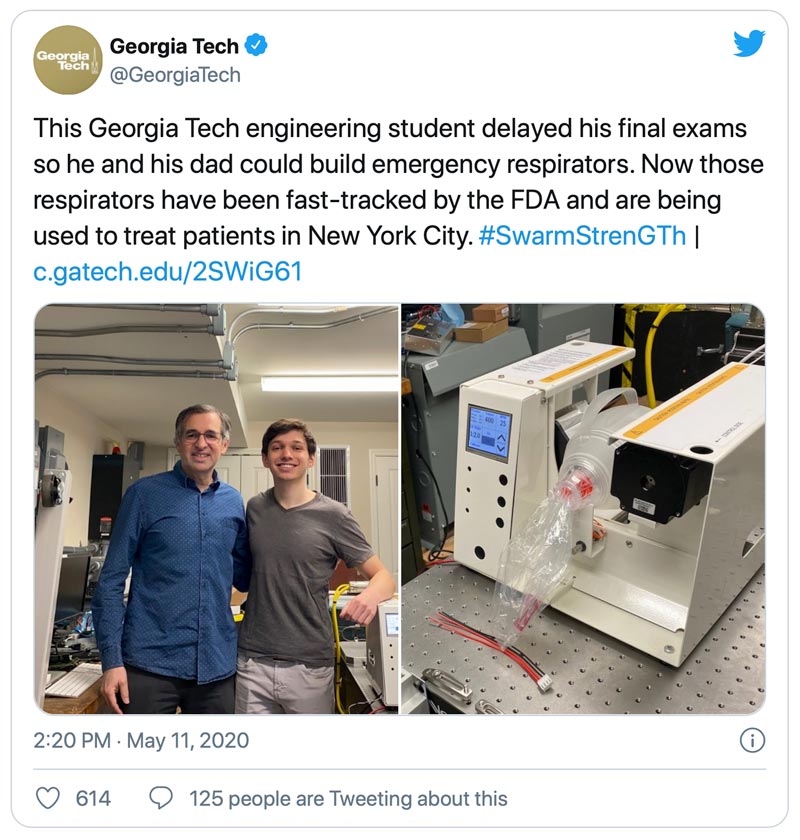

Heeding The Call

This Georgia Tech engineering student delayed his final exams so he and his dad could build emergency respirators. Now those respirators have been fast-tracked by the FDA and are being used to treat patients in New York City. #SwarmStrenGTh

Yellow Jacket Company Proposes Deployable Chest X-Ray Device to Diagnose and Monitor Covid-19

Founded in 2016, as Micro C Imaging LLC in Savannah, Georgia, by two Tech graduates, OXOS Medical is responding to the call from the National Science Foundation for proposals for specialized equipment to be considered under the Rapid Response Research funding mechanism to develop processes and actions to address the global coronavirus pandemic.

OXOS is a startup in the Advanced Technology Development Center’s Accelerate portfolio of companies, and its Micro C handheld X-ray device is its lead product.

With modifications to the Micro C, a certified nurse assistant, or other trained personnel, could be triaged to an asymptomatic patient’s home and rapidly collect a chest X-ray either in conjunction with a flu swab, oral temperature, and pulse oximetry reading — or without, depending on resource availability.

Citing the practicality of an OXOS solution, Evan Ruff, co-founder and CEO, said with the deployment of this system, the exam could be executed by a resource with very little training. A test could likely be completed in less than 15 minutes, he said.

“In this case, it is likely that a single mobile unit could examine between 20-30 patients in a day. A moderately sized fleet of mobile examiners has the potential to save thousands of emergency room visits per day,” Ruff said.

New Practicum Designed to Accelerate Covid-19 Solutions

Through a new course titled Global Technology Innovation Practicum, the Scheller College of Business is demonstrating how a small cohort of students can make an impact of global scale in the midst of a pandemic.

The course is meant to build on the fundamentals of Scheller’s TI:GER® (Technology Innovation: Generating Economic Results) program while narrowing its focus to innovating for the Covid-19 crisis.

“What is different about this coursework is that it directly and immediately responds to a global pandemic. It draws on the same pedagogy of our typical practicums, yet has huge implications for the issues top of mind around the world,” says Executive Director and Academic Director of TI:GER Jonathan Giuliano.

Grey HR Article Div

Donnians Lucas Abreu de Oliveria shows the volume of rice purchased by the Miratus Badminton Association to distribute to Brazilian families, in part, thanks to funds donated by the Global Social Entrepreneurship Vertically Integrated Project team at Georgia Tech.

VIP Students Help Brazilian Nonprofits Respond to Covid-19

When the Covid-19 pandemic struck South America’s most populous country, students in Tech’s Global Social Entrepreneurship Vertically Integrated Project (VIP) knew they had to act quickly.

“I immediately knew that our partner organizations were going to have to take on an unprecedented role that drastically differed from their typical charitable routines,” said Sam Chappell, a Yellow Jacket from Savannah who graduated in May 2020 with a degree in international affairs.

The VIP group, a team of 13 students from across campus, decided to use funds earmarked for future projects to send immediate aid to those organizations. The funds enabled them to pivot from providing high-energy youth training programs to delivering urgently needed food and sanitary supplies for at-risk residents in Rio de Janeiro.

“This effort even resulted in the creation of temporary jobs for people to help with coordination of the whole project,” Chappell said.

Img: SLS Internship

SLS students gather at the Lake Claire Community Land Trust during their monthly Plantlanta Volunteer Day (2019). Photo by Jessica Copenhaver.

Third Annual SLS Summer Internship Program Pairs Students With Partners to Support Georgia During Covid-19

According to a survey conducted by the talent-acquisition software company Yello, 35% of student internships were canceled, and 24% had to go virtual for Summer 2020 because of the coronavirus pandemic. Yello surveyed more than 900 college students.

But Georgia Tech's Serve-Learn-Sustain (SLS) program, which offers students from all colleges opportunities to collaborate with diverse partners on key sustainability challenges, continued to provide internship opportunities for students amid the global crisis.

For Summer 2020, which saw SLS’s largest cohort since the program’s inception in 2017, the program connected 44 students with employers through a rigorous application and interview process. Students interned with government, community, nonprofit, academic, and business partners through SLS and its collaborators, the Georgia SMART Community Corps Program, and the Sea Level Sensor Project.

"When the internship application and interview process began back in January, no one could have anticipated the situation with Covid-19," said Kristina Chatfield, SLS program and operations manager. "Student interns were being offered their summer placements the first week that students moved off campus, and we had no way of knowing at that time what would transpire. Within a few weeks, working in collaboration with our program partners and internship hosts, we were able to develop a plan to host the internship program entirely online."

Recovery

As the world grapples with the new reality imposed by the global pandemic, Georgia Tech remains front and center in the multifaceted attempts to move us all forward togehter.

Sarah Farmer, a research scientist with HomeLab in the Center for Advanced Communications Policy, is evaluating Covid-19 testing kits submitted as part of the National Institutes of Health's $500 million Rapid Acceleration of Diagnostics (RADx) initiative.

Factoring Human Factors Into Covid-19 Testing

Factoring Human Factors Into Covid-19 Testing

Georgia Tech’s School of Public Policy’s HomeLab, within the Ivan College of Liberal Arts, has been playing a crucial role in the national effort to vet new testing technologies to help slow the spread of Covid-19. Researchers there have been helping evaluate candidate tests to ensure end users would be able to correctly complete the tests and record accurate results.

Whereas researchers from other Georgia Tech units, such as the Institute for Electronics and Nanotechnology, the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory University, and Children’s Healthcare of Atlanta, have been concerned with how well a test detects the virus, and the engineers have been interested in how technically ready a device is for manufacturing at scale, the HomeLab team has been focusing on the human factors involved in getting a correct test result. The team has been exploring issues such as: “Is it too complicated? Do they have to assemble something? Are there pieces that could break or be misplaced? How are the results differentiated?” said Research Scientist Sarah Farmer, who is also HomeLab’s project manager.

All told, about 60 tests would have been evaluated by the end of the process, which should be completed by October, in time for the cold and flu season.

Gold HR Article Div

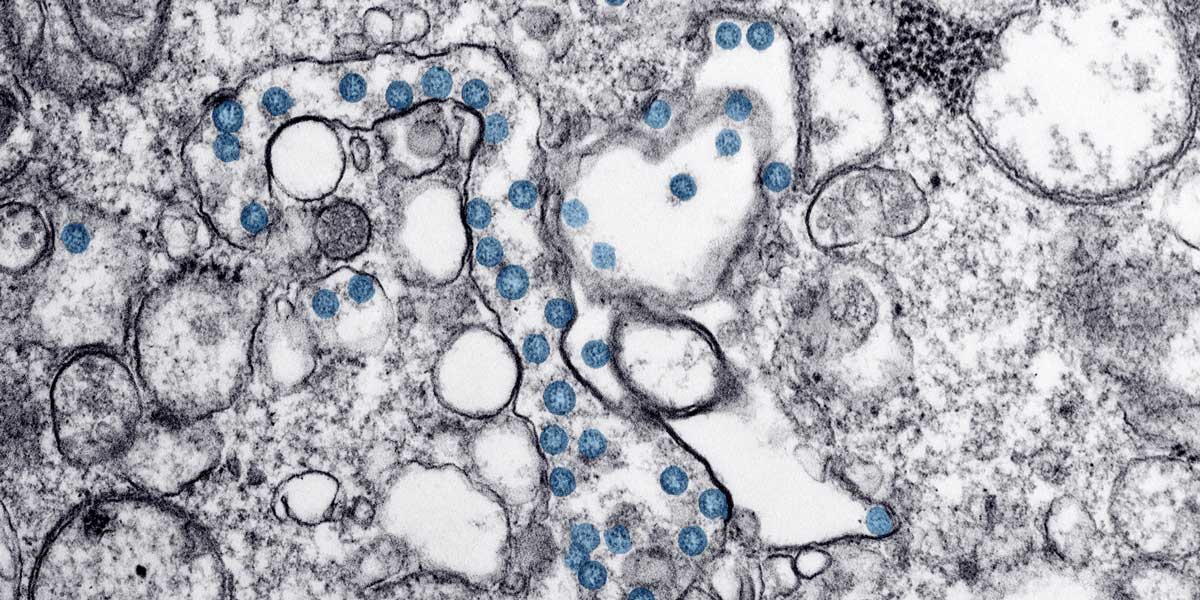

Img: Tech CDC Collab Antibodies

Transmission electron microscope image from the first U.S. case of COVID-19. (Credit: Centers for Disease Control and Prevention: Hannah A. Bullock and Azaibi Tamin)

Tech, CDC Collaborate on Coronavirus Antibody Research

Using simulated components of the coronavirus’ distinctive spike proteins, Georgia Tech researchers and colleagues at the Centers for Disease Control and Prevention (CDC) are producing antibodies that could lead to improved testing techniques for the virus, potential treatments for those infected with it — and ultimately, perhaps, a vaccine.

The antibodies are produced by mice that are exposed to peptides — short chains of amino acids —produced from the genetic code of the virus. The researchers choose distinctive components of the viral surface, create the peptide structures in the laboratory, and place them onto nanoparticles to create artificial immunogens designed to stimulate the immune systems of the mice.

The antibodies are produced in collaboration with the CDC’s Immunodiagnostic Development Team, Reagent Diagnostic Support Branch, Division of Scientific Resources, National Center for Emerging Zoonotic Infectious Diseases. Scientists at both institutions are using the antibodies to study antigen binding in the coronavirus.

“We do a series of immunizations with components of the proteins from the coronavirus that we believe are particularly important and able to be seen by the mouse immune system,” said M.G. Finn, who co-leads the project as chair of Georgia Tech’s School of Chemistry and Biochemistry. “The immunizations and follow-up boosts allow us to provide samples of immune system cells from the mice. CDC researchers use them to generate thousands of candidate antibodies that we then use to test binding of the antibodies to portions of the virus.” Finn is chair of Georgia Tech's School of Chemistry and Biochemistry and James A. Carlos Family Chair for Pediatric Technology.

Alumni and Tech Supporters Show Strength of the Swarm

In Spring 2020, alumni and Georgia Tech supporters mobilized quickly to provide hope to students experiencing hardship related to the pandemic. Within a week of students having to vacate campus unexpectedly, hundreds began using the #SwarmStrenGTh hashtag on social media to share messages and videos of encouragement. The hashtag has now generated hundreds of thousands of social media impressions, as Yellow Jackets and other Institute supporters continue to rally behind it.

That social media trend quickly evolved into an intensive effort to support students financially affected by the pandemic. As the scale of the crisis became apparent, the Institute established the Covid-19 Student Relief Fund. Supported in part by gifts through the Alumni Association’s Roll Call, the fund has provided relief to more than 2,000 students, including Monica Sierra Aparicio, a building construction major.

“Georgia Tech’s support during this pandemic gives me a lot of hope that we’ll overcome this,” said Sierra.

Unrestricted gifts to Roll Call totaled more than $1.4 million from March through June 2020. Thousands contributed, including Laney Light, a music technology master’s student. She donated the $379 student fees refund she received from Tech.

“That was money I wasn’t expecting to get back,” she said. “My family has been fortunate that our financial situation hasn’t really been affected, so I wanted to give that money back to students who needed it more than I did.”

Georgia Tech continues to offer pandemic-related grants and has, as of Sept. 8, 2020, awarded $1,831,827.51 to 2,126 students.

Tech Paper Addresses Possibility of Recovered Covid-19 Patients’ Immunity Cutting Risk of Expanded Economic Activity

While primary attention has been given to the number of Covid-19 deaths and new cases, a separate statistic — the number of recovered patients — may be equally important to the goal of minimizing the pandemic’s infection rate.

The presumed immunity of those who have recovered from the infection could allow them to safely substitute for susceptible people in certain high-contact occupations such as healthcare.

Dubbed “shield immunity,” the anticipated protection against short-term reinfection could allow recovered patients to expand their interactions with infected and susceptible people, potentially reducing overall transmission rates.

New modeling of the virus’ behavior suggests that an intervention strategy based on shield immunity could reduce the risk of allowing the higher levels of human interaction needed to support expanded economic activity.

A paper describing the modeling behind the concept of shield immunity was published May 7, 2020, in the journal Nature Medicine by a team of researchers from Georgia Tech, Princeton University, and McMaster University.

Krishnendu Roy is a professor and the Robert A. Milton Chair in the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory.

Researchers Receive NIH Funds for Adjuvant Research to Boost Coronavirus Vaccines

The National Institute of Allergy and Infectious Diseases, part of the National Institutes of Health (NIH), has granted funding for the screening and evaluation of certain molecules known as adjuvants that may improve the ability of coronavirus vaccines to stimulate the immune system and generate appropriate responses necessary to protect the general population against the virus.

Adjuvants are used with some vaccines to help them create stronger protective immune responses in persons receiving the vaccine. Tech researchers will screen a library of various adjuvant combinations to quickly identify those that may be most useful to enhance the effects of both protein- and RNA-based coronavirus vaccines under development.

“We are trying to understand how adjuvant combinations affect the vaccine response,” said Krishnendu Roy, a professor and Robert A. Milton Chair in the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory. “We will look at how the immune system shifts and changes with the adjuvant combinations. The ultimate goal is to determine how to generate the most effective, strongest, and most durable immune response against the virus.”

Blue HR Section Div

Though the 2019-20 fiscal year came to a close in the midst of the most harrowing period in living memory — with the world reeling from the effects of the coronavirus pandemic on top of extreme social strife — it was a year that presented us with much opportunity. The academic, research, and community outreach efforts undertaken during this past fiscal period have, indeed, positioned us solidly to move forward with our strategic plan vision for the next 10 years.

So now we look forward to further building on our strong foundation, confident that our legacy of excellence augurs well for all that we have in mind to address the biggest local, national, and global challenges, as we relentlessly seek to serve the public good and improve the human condition.